Algorithmic robotics is a field of study that focuses on the design and analysis of algorithms for controlling robotic systems. These algorithms are used to solve various problems in robotics, such as planning paths for a robot to move from one location to another, coordinating the actions of multiple robots, or interpreting sensor data to understand the robot’s environment.

Here are some key areas of focus in algorithmic robotics:

Motion Planning:

This involves developing algorithms that can determine a sequence of movements or actions that a robot should take to achieve a specific goal, such as reaching a target location or picking up an object. This can be a complex problem, especially in environments with obstacles or in situations where the robot has many degrees of freedom (e.g., a robotic arm with multiple joints). Motion planning algorithms rely on various techniques, such as graph-based search methods, probabilistic approaches, or optimization strategies. These algorithms consider factors such as the robot’s kinematics, dynamics, and sensor information to generate efficient and safe motion plans. Additionally, motion planning algorithms need to take into account uncertainties and dynamic changes in the environment to ensure robust performance. By continuously updating plans based on real-time sensor data, robots can adapt to unexpected obstacles or changes in the environment, making motion planning a crucial aspect of autonomous robotics.

Seminal papers to read about motion planning:

- Sampling-based algorithms for optimal motion planning by S. Karaman and Emilio Frazzoli. This paper rigorously analyzes the asymptotic behavior of the cost of the solution returned by stochastic sampling-based path planning algorithms as the number of samples increases. It introduces new algorithms, namely, PRM* and RRT*, which are provably asymptotically optimal.

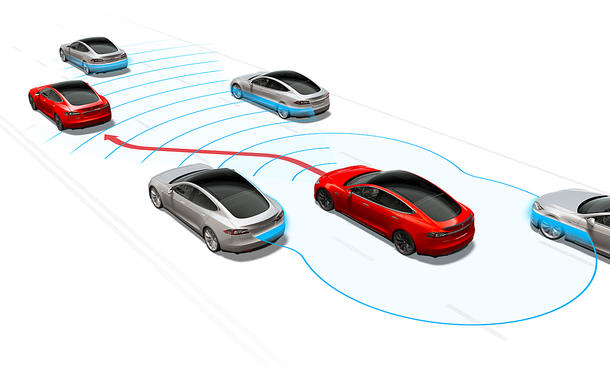

- A Survey of Motion Planning and Control Techniques for Self-Driving Urban Vehicles by B. Paden, Michal Cáp, Sze Zheng Yong, Dmitry S. Yershov, and Emilio Frazzoli. This paper surveys the current state of the art on planning and control algorithms with particular regard to the urban setting.

- Motion Planning Among Dynamic, Decision-Making Agents with Deep Reinforcement Learning by Michael Everett, Yu Fan Chen, and J. How. This work extends previous approaches to develop an algorithm that learns collision avoidance among a variety of types of dynamic agents without assuming they follow any particular behavior rules.

- A Review of Motion Planning for Highway Autonomous Driving by Laurene Claussmann, Marc Revilloud, D. Gruyer, and S. Glaser. This paper presents a review of motion planning

further reading:

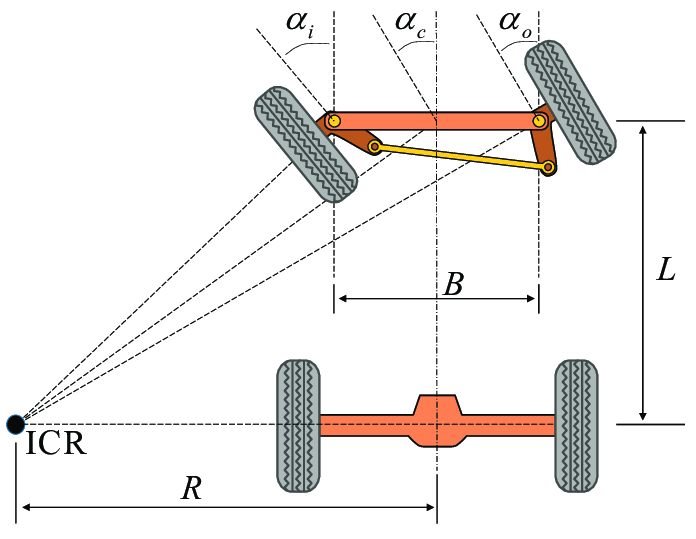

- Motion planning of non-holonomic robots like Ackerman steering

- Non-holonomic modeling of mobile robots

Multi-Robot Systems:

When multiple robots are working together, algorithms are needed to coordinate their actions and ensure they work efficiently as a team. This can involve a wide range of tasks, including dividing up work among the robots, avoiding collisions, synchronizing their actions, performing complex cooperative behaviors, and making informed decisions based on real-time data. These cooperative behaviors go beyond simple coordination and can include sophisticated strategies such as task allocation, formation control, and dynamic role assignment.

Additionally, multi-robot systems can exhibit emergent behaviors, where the collective actions of the robots result in intelligent and efficient problem-solving. For example, in cooperative transport, robots can strategize and distribute the load to optimize energy consumption and avoid overloading any individual robot. In cooperative mapping, robots can collaborate to explore and map an unknown environment by sharing their sensor data and constructing a comprehensive map. To further enhance the capabilities of multi-robot systems, advanced techniques such as swarm intelligence and machine learning can be employed. Swarm intelligence allows the robots to collectively make decisions based on local interactions and simple rules, enabling them to adapt to changing environments and handle unpredictable situations.

Machine learning algorithms can enable robots to learn from their experiences and improve their performance over time, leading to more efficient and effective collaboration. In summary, multi-robot systems are a fascinating and rapidly evolving field, where the coordination and cooperation of multiple robots can unlock a wide range of possibilities. From task allocation to emergent behaviors and advanced techniques, these systems hold immense potential to revolutionize various domains, including search and rescue operations, automated warehouse management, and surveillance missions. Efficient coordination and communication among the robots remain crucial components for achieving success in this exciting area of research and development.

Seminal papers to read about multi-robot systems:

- Cooperative Object Transport in Multi-Robot Systems: A Review by Elio Tuci, M. Alkilabi, and O. Akanyeti. This paper reviews advancements in multi-robot systems designed for cooperative object transport. It provides a comprehensive summary of the scientific literature in this field, focusing on transport strategies such as pushing-only, grasping, and caging.

- Coordinated Control of Multi-Robot Systems: A Survey by J. Cortés and M. Egerstedt. This paper discusses a class of problems related to the assembly of preferable geometric shapes in a decentralized manner through the formulation of descent-based algorithms defined with respect to team-level performance costs.

- Simultaneous task allocation and planning for temporal logic goals in heterogeneous multi-robot systems by Philipp Schillinger, Mathias Bürger, and D. Dimarogonas. This paper describes a framework for automatically generating optimal action-level behavior for a team of robots based on temporal logic mission specifications under resource constraints. The approach optimally allocates separable tasks to available robots, identifying sub-tasks in an automaton representation of the mission specification and simultaneously allocating the tasks and planning their execution.

Perception and Sensor Fusion:

Robots often have multiple sensors (e.g., cameras, lidar, accelerometers) that provide different types of data about the environment. These sensors allow the robot to perceive and gather information from its surroundings. The role of algorithms becomes crucial in helping the robot interpret this data and create a comprehensive understanding of its environment. By processing data from these various sensors, robots are able to develop a holistic perception of their surroundings.

- The cameras play a vital role in enhancing the capabilities of robots by enabling them to capture and process visual information. This, in turn, empowers robots to effectively identify various objects, detect potential obstacles in their surroundings, and recognize complex patterns. With the aid of cameras, robots can navigate through their environments with more precision and efficiency, contributing to their overall functionality and performance.

- Lidar sensors, on the other hand, utilize laser beams to measure distances and create detailed maps of the environment. These state-of-the-art sensors employ laser technology for distance measurement purposes, as well as for constructing highly accurate and comprehensive maps of the surroundings. By employing laser beams, lidar sensors are able to obtain precise data regarding the distances between objects and accurately delineate their exact locations in the environment. The intricate maps generated by these advanced sensors provide an in-depth insight into the surrounding terrain, offering valuable information for a wide range of applications and industries. Lidar sensors, with their laser-based capabilities, play a vital role in various sectors such as autonomous vehicles, aerial mapping, and urban planning, where precise and detailed mapping is of paramount importance.

- Accelerometers are a vital component that greatly contributes to enhancing the robot’s comprehension of both movement and gravity. This invaluable feature enables the robot to gather valuable insights, which are crucial for navigating its surroundings effectively. The integration of accelerometers expands the robot’s understanding of its environment, thereby enabling it to operate with a heightened level of precision and efficiency.

- Wheel encoders play a crucial role in obtaining a vast amount of high-frequency odometer data.

The challenge lies in combining the data from these diverse sensors in a meaningful way. Algorithms are employed to synthesize the information and generate a coherent representation of the environment. This synthesis enables the robot to make informed decisions, plan its actions, and navigate its surroundings effectively. In summary, the integration of multiple sensors and the application of intelligent algorithms empower robots to perceive and comprehend their environment in a more detailed and comprehensive manner. This allows them to interact with and manipulate their surroundings in a way that closely resembles human cognitive abilities.

Machine Learning for Robotics:

Machine learning algorithms can be used to enable robots to learn from experience and improve their performance over time. This can involve techniques such as reinforcement learning, which allows the robot to learn by trial and error and make informed decisions based on previous experiences. Additionally, supervised learning allows the robot to learn from labeled training data, enabling it to understand patterns and make accurate predictions. By implementing these advanced techniques, robots can become more intelligent and adaptable, enhancing their ability to interact with the environment and carry out complex tasks.

Control Algorithms:

These are highly complex and advanced algorithms that determine precisely how a robot should respond to its immediate state and the surrounding environment in order to effectively achieve its various goals. This crucial process involves incorporating both feedback control, where the robot adjusts its actions based on continuous evaluation of its current state, and feedforward control, where the robot predicts and anticipates the potential effects of its actions, allowing it to plan its movements accordingly. It is worth highlighting that these algorithms play a pivotal role in enabling robots to dynamically adapt and make real-time decisions based on their nuanced surroundings and desired outcomes.

By diligently and continuously analyzing data from an array of sensors, robots can autonomously fine-tune their behavior, optimizing their performance and enhancing their overall efficiency. This is particularly plausible through feedback control, which empowers robots to actively respond to changes in their environment while ensuring the effectiveness and efficiency of their actions. Moreover, feedforward control equips robots with the remarkable ability to anticipate potential outcomes, subsequently strategizing their actions in a manner that maximizes their chances of achieving success. The utilization of these sophisticated algorithms provides robots with the profound ability to adeptly navigate and interact with remarkably intricate environments while seamlessly engaging with humans. As a result, robots powered by these advanced algorithms can harmoniously accomplish an extensive range of intricate tasks with unparalleled precision, autonomy, and overall effectiveness.

In all these areas, the focus is on developing algorithms that are efficient, reliable, and robust to uncertainties in the environment or the robot’s sensors and actuators.